Cost of Ceilume Thermoformed Ceiling Panels Compared to Mineral Fiber Ceiling Panels in Fire-Sprinklered Office Building

By Bill Kneeland, PE and Michael Chusid, RA

Download Cost Study

Includes the text from this article as well as the data and results of both Investigation One and Investigation Two.

A thermoformed drop-out ceiling panel has recently been tested and approved for installation beneath fire sprinklers. Until now, drop-out ceiling products have had limited performance and visual appeal. In contrast, the thermoplastic panels, made by Ceilume, look great and meet performance requirements for commercial, institutional, residential, and other architectural projects.

Ceilume's panels are made of rigid vinyl either 0.013 or 0.030 inches thick and can be installed in standard 15/16" T-bar ceiling grid. When exposed to fire, the thermoplastic softens, sags, and drops-out of the grid at a temperature below that required to activate sprinklers. Sprinklers can then operate unimpeded to extinguish fire. Drop-out ceiling panels are allowed under NFPA 13 - Standard for the Installation of Sprinkler Systems, and Ceilume's panels have been approved by UL, FM, IAPMO-UES, and other building evaluation services.

When drop-out ceiling panels were proposed for an 110,000 sq.ft. office building in Oklahoma City, we were asked to prepare a detailed construction cost estimate comparing thermoformed and mineral-fiber ceiling panels. In particular, our client wanted to know how Ceilume's panels affect total project costs including sprinkler design and installation. We found that Ceilume panels installed beneath sprinklers are significantly less expensive than mineral fiber panels with penetrating sprinklers.

Cost Savings

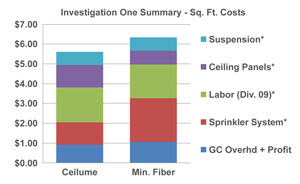

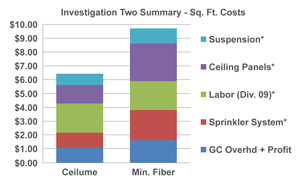

We investigated two scenarios and found that the Ceilume approach generated savings ranging from $3.29 to $0.72 per sq. ft. The first value represents 2 x 2 ft. panels and compares Ceilume to 3/4" thick tegular mineral fiber panels; the second value represents 2 ft. x 4 ft. panels and compares Ceilume to standard 1/2" thick mineral fiber panels.

Investigation 1: Ceilume panels are 0.013" thick Polyline style installed beneath sprinklers. Mineral fiber panels are 5/8" thick square-edge, fissured panels equal to Armstrong 755 installed with recessed sprinklers. Both are 2' x 4'. and white.

Investigation 2: Ceilume panels are 0.013" thick Polyline style installed beneath sprinklers. Mineral fiber panels are 3/4" thick regular tegular panels equal to Armstrong 577 Cirrus installed with recessed sprinklers. Both are 2' x 2' and white.

The affordability of any installation depends on project conditions, products, and performance levels required. Thermoplastic panels, for example, are more affordable than tegular and decorative mineral fiber panels and competitively priced with ordinary mineral fiber products.

While labor to install panels is similar regardless of material, cutting individual thermoformed panels for perimeter units may cost slightly more than scoring and breaking square-edged mineral fiber tiles and about the same as trimming tegular panels. Thermoformed panels, however, nest compactly and several panels can be cut simultaneously with aviation snips. Our estimate is based on open-shop wages and savings are likely to be even greater in areas with prevailing wage rates.

Concealing sprinklers above ceilings reduces cost of sprinklers. For example, drop-out ceilings eliminate need to extend pipes from sprinkler mains (usually located just under floor or roof structure) to ceiling elevation, and the piping used to position sprinklers at panel centers. This enables layout of sprinklers to be optimized and eliminates need for installation drawings to coordinate sprinklers with ceiling installers. Non-appearance grade sprinklers can be used and finishing rings and escutcheons can be eliminated. Ceiling installers do not have to cut holes for sprinklers. And sprinkler installers do not have to return to project to adjust sprinkler locations after ceiling installation.

Other Cost Implications

Other factors, not included in estimate, also impact affordability of thermoformed drop-out ceilings. For example, simplifying ceiling and sprinkler coordination can save valuable time when scrambling to complete ceiling before project completion deadline. More, thermoformed panels are not affected by moisture and can be installed before interior humidity has stabilized.

Life cycle considerations for thermoplastic panels are better than for mineral fiber panels: Thermoplastic panels are washable and easily cleaned and will not require replacement due to sagging or mold caused by moisture or humidity. Thermoplastic panels will not stain or discolor, and can simply be wiped clean if roof or plumbing leaks occur or sprinklers discharge. And replacement panels can be installed without cutting openings for sprinklers.

Thermoformed panels reduce cost of shipping and storage because they are lightweight, thin, and nest for compact packaging. Light weight also makes panels easier to handle, increases productivity, and reduces lifting-related injuries. Handling is also simplified because thermoplastic panel installation does not require the ventilation, dust respirators, and skin protection required when working with mineral fiber.

Unlike mineral fiber, thermoplastic panels are robust and not easily damaged. Edges and corners, for example, resist breakage during installation and when panels are removed for above-ceiling access.

Installing sprinklers above ceiling also provides protection against accidental impact or tampering that could discharge sprinklers and cause water damage. It also reduces potential that drywall compound or paint will get on sprinklers and require call backs.

Practical Considerations

The thinness and light weight of Ceilume panels reduce handling costs and simplifies installation. Several Panels can be cut at a time using aviation shears.

While installing thermoformed ceilings is easy enough for homeowner do-it-yourself projects, commercial contractors are often wary of unfamiliar products. Ceilume provides sample panels to subcontractors so they could get feel of product prior to submitting bids. Using drop-out panels has important life-safety implications and installers must understand and observe requirements stated in product evaluation reports and as acceptable to authorities having jurisdiction.

Ceilume panels can also be used for projects without sprinklers or with penetrating (non-concealed) sprinklers. The product has a good environmental profile since they are GreenGuard Gold certified for indoor air quality and recyclable as Type 3 plastic. They have modest acoustical properties and the manufacturer offers special backer pans that boost noise reduction coefficients. In addition to a variety of colors and faux wood and metal finishes, panels are also available in translucent and transparent material that can be used for back-lit luminous ceilings. Their smooth and cleanable surface complies with FDA requirements for food handling areas and FEMA requirements for flood-prone areas. Finally, the panels are available in dozens of patterns ranging from shallow relief to deeply molded surfaces in a variety of historic and contemporary styles.

Authors: Bill Kneeland is an Oklahoma City-based design-builder and construction cost estimator; email bkiengr@gmail.com. Michael Chusid is an architect and a consultant specializing in evaluating innovative building products; email michael@chusid.com.

A related article, "Bench Test: A Check-in on Drop-out Ceilings," appears in Walls & Ceilings September 2014.